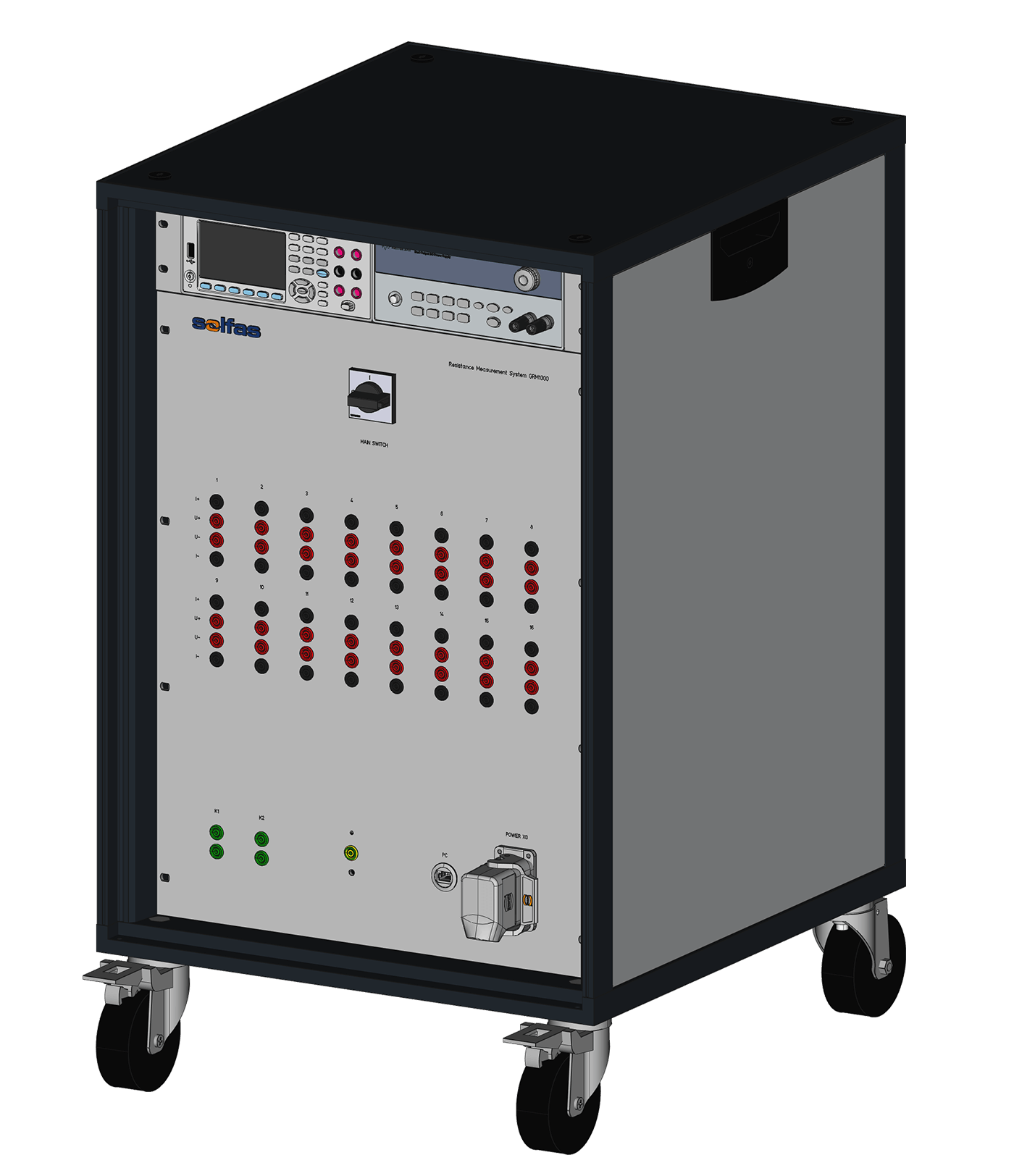

Heat Run Resistance Measurement System GRM1000

Highlights

This solution was specially designed for resistance measurement after heat run tests on transformers, chokes, electrical motors and other products according to the standard IEC60076.

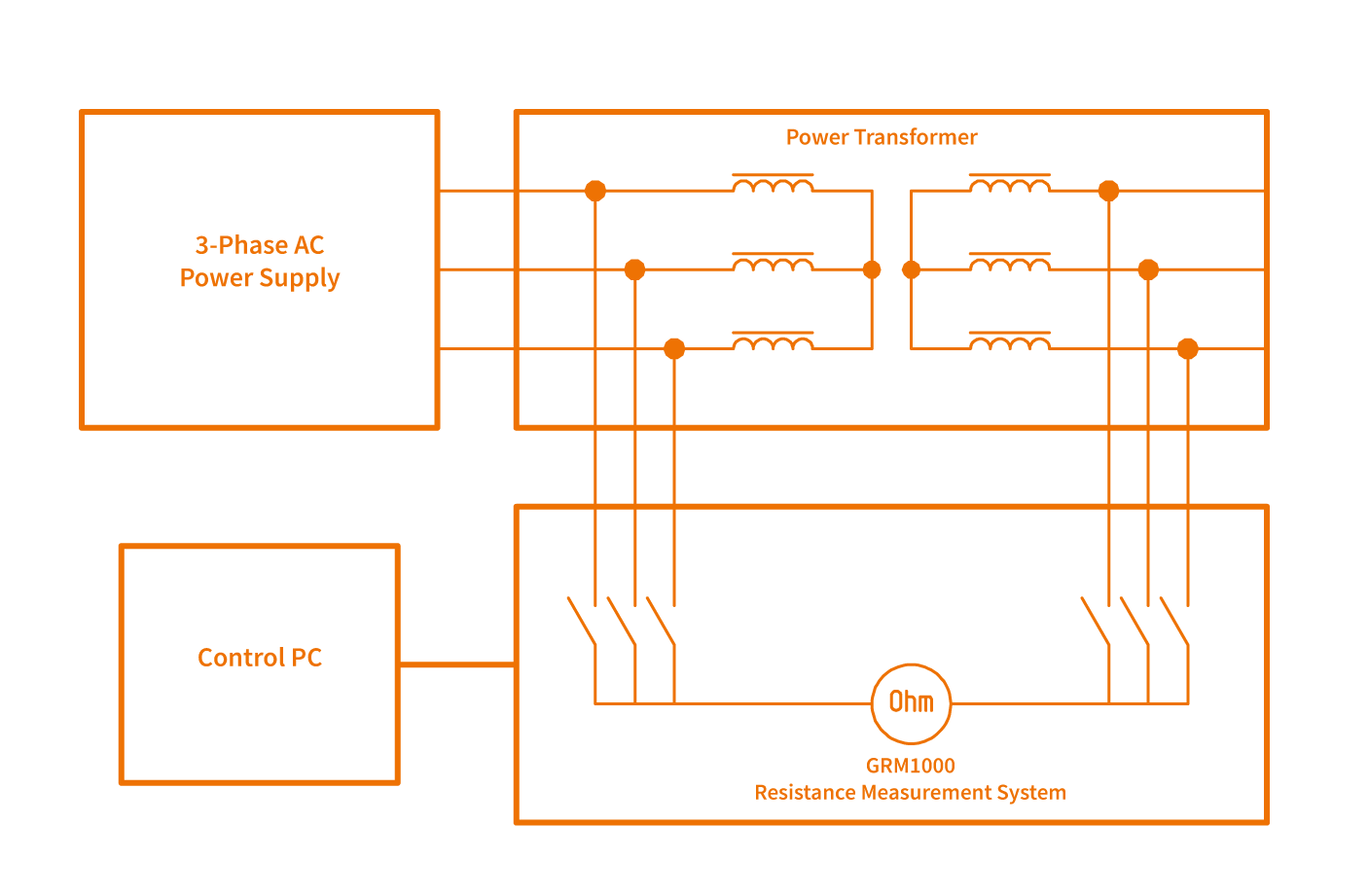

System Setup

Requirements

During heat run tests the maximum internal winding temperatures must be checked in order to verify the product design. The maximum internal winding temperature can determined by cyclic measurement of winding resistance during the cool down phase after the heat run test. This has to be done at all windings of a transformer.

Challenges

For this task a lot of resistance measurements need to be done in a defined time interval. The resistances can be very low and the winding inductance can be very high. During heat run test the voltages and currents can be high, the switchover to resistance measurements must be done quickly after finish of the heat-run test.

Our Solution

The transformer is connected to the measuring system before the heat run test. The voltage proof inputs allow a permanent connection during the heat run test. When the heat run test is finished, then the measurement system is activated and does a cyclic resistance measurement on all windings according to the configuration. Our software controls the measurment system and transfers the measurement data to the PC, where they are displayed, stored and evaluated.

- Winding Resistance

- Winding Temperature after Heat-run from Calculation

- Ambient Temperature

- Remote Control by PC Software

- Networking with Ethernet and WLAN

- Customized Data Logger Software

- Data Export to Excel

- Consulting

- Planning

- Rack construction

- Software development

- Commissioning on site

- Operator training