Product Description

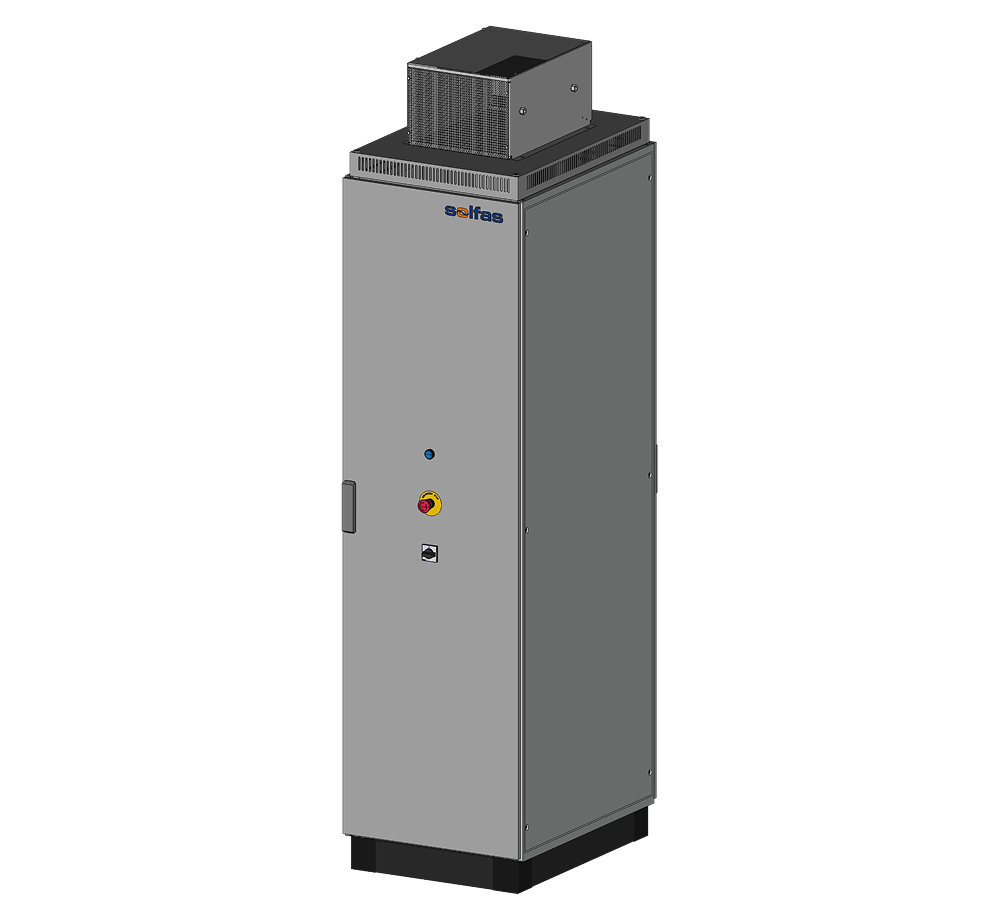

The CTS1000 Series is a state-of-the-art test system specifically designed for precise battery and ultra-capacitor testing. Equipped with a bidirectional power supply, precision measurement devices, and comprehensive safety features, the CTS1000 delivers maximum accuracy, safety, and reliability for demanding applications.

System Overview – Modular Concept

It is easily scalable and can be flexibly configured for your specific requirements.

Base System

At the core of the tester is a precision high-current, bidirectional power supply with flexible Constant Voltage (CV) and Constant Current (CC) control, enabling accurate charging and discharging of capacitor and battery modules.

- Delivers high-precision measurement of voltage, current, and charge

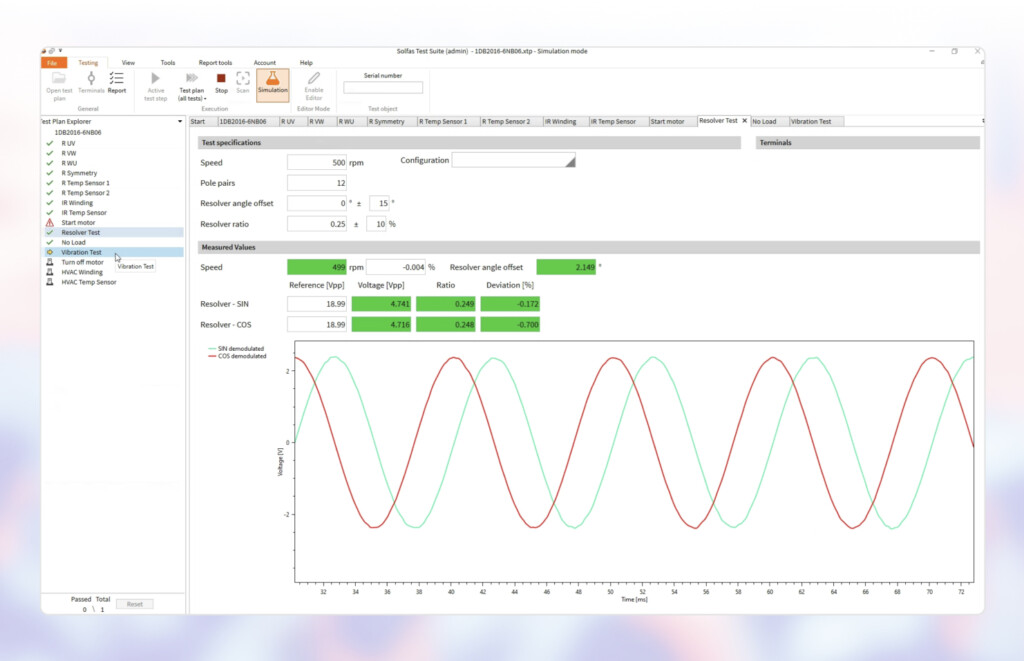

- Supports freely configurable test sequences for advanced measurements such as capacitance and equivalent series resistance (ESR)

- Operated via an industrial PC with dedicated control software for real-time monitoring, automation, and parameter management

- Integrated modular safety system featuring interlock control, emergency stop handling, and test enable logic in accordance with industrial safety standards

- Offers database connectivity (e.g., SQL-based systems) for centralized data logging, test result storage, and full traceability across production batches

- Software supports custom workflows, MES integration, and test/calibration parameter handling

This base system combines electrical precision, software flexibility, industrial safety, and data integrity—making it ideal for both R&D and high-throughput production environments.

Safety Test Option

For enhanced electrical safety validation, the tester can be equipped with an integrated GHV2000 Safety Tester, which provides high-performance insulation and dielectric strength testing. Key features include:

- High-voltage testing up to 6 kV AC / 8 kV DC, up to 500 VA

- Insulation resistance measurement up to 100 GΩ

- Automated switching of power and auxiliary lines for efficient test sequencing and operator safety

This integrated safety test option enables full high-voltage compliance verification within a single, automated testing environment, minimizing external setup and reducing testing time.

Communication Option

The tester is equipped with CAN, LIN, and UART interfaces that enable communication with capacitor or battery management systems. Key diagnostic capabilities include:

- Cell balancing check: Monitor and evaluate balancing performance across cells

- Voltage monitoring: Validate responses to cell overvoltage/undervoltage thresholds.

- Sensor testing: Monitor temperature and auxiliary sensor data for verification

- Communication robustness check: Test protocol handling, message timing, and error response across interfaces

Programming Option

The tester includes a robust production programmer, compatible with a broad range of target devices and programming interfaces such as SPI, JTAG, and UART.

- Designed for rugged conditions and high-throughput operation in industrial environments

- Features high-voltage proof switching, enabling reliable one-time connection for both programming and testing

- Supports firmware upload via CAN, LIN, or UART, allowing direct flashing over system communication interfaces

This option ensures efficient, automated in-circuit programming within the production workflow, minimizing handling and cycle time.

Calibration Option

The system supports calibration and adjustment of capacitor or battery management systems using ISO 17025-calibrated reference instruments for high-precision validation.

- Enables adjustment and calibration of internal measurements for voltage, current and temperature

- Supports automated calibration sequences, reducing operator influence and ensuring consistency

- Calibration parameters are stored with full traceability, enabling audit-ready documentation and historical tracking

Ideal for ensuring measurement accuracy and compliance with quality standards in production and development environments.

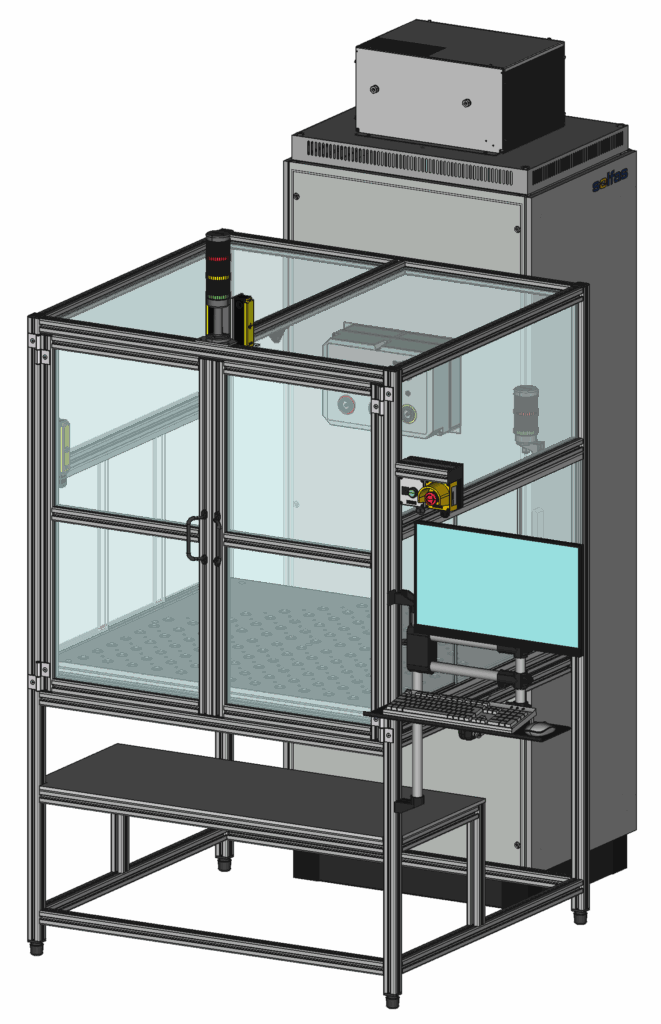

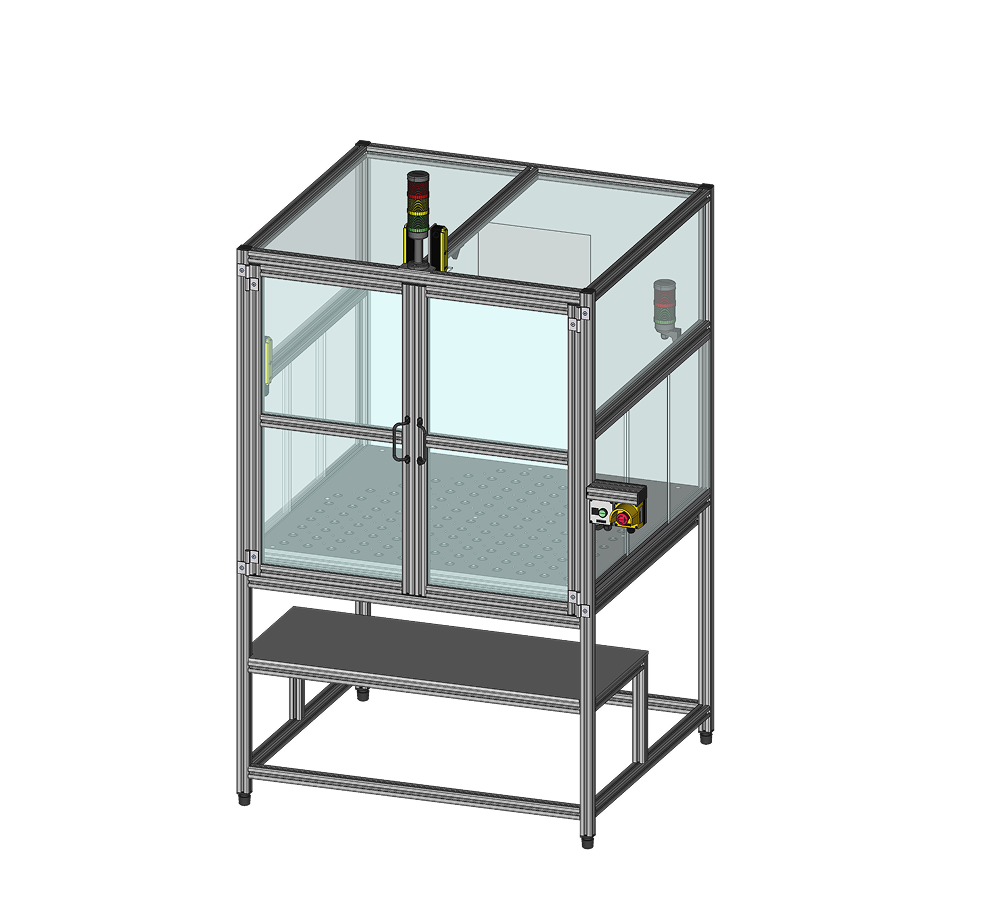

Test Cabin Option

Designed for seamless integration into automated production environments, the Test Cabin Option provides a compliant and safe solution for high-voltage testing in accordance with EN 50191.

- Equipped with safe voltage monitoring, automatic door locks, and warning indicators to meet safety regulations

- Includes a standard interface to roller conveyor systems for smooth material flow and minimal handling

- Supports automated test sequencing and external control integration via industrial I/O or communication protocols

This option ensures both operator safety and line efficiency, making it ideal for scalable, high-throughput production setups.

Technical Specifications

| Model | CTS1000-15-70 | CTS1000-15-210 | CTS1000-30-210 |

|---|---|---|---|

| Output power | ±15kW | ±15kW | ±30kW |

| Output voltage | 0–70V | 0–210V | 0–210V |

| Output current | ±0–300A | ±0–150A | ±0–300A |

| Measurements | High-precision voltage & current measurement | ||

| Interfaces | CAN (3×), LIN, UART | ||

| Aux supply | 0–60V, 10A, 200W | ||

| High voltage test | Up to 6kV AC / 100mA | ||

| Insulation test | 200–6000V DC, up to 100 GΩ | ||

| Safety | Emergency stop, locks, discharge monitoring | ||

| Dimensions | 600×2100×800 mm | ||

| Weight | 270 kg | ||

Applications

Safety Features

Highest Safety Standard

Redundant circuit with built-in self-monitoring. Meets highest safety requirements:

ISO 13849-1 PL e

Test Cabin

Safety test cabin with 4 protection doors and monitored locks

Safe Discharge

Safe redundant voltage monitoring for controlled discharge

Programmable Safety Control

For easy adaption to individual requirements

Discharge Resistor

High power discharge resistor for ultra capacitors with high energy

Warning lights

Green and red warning lights according to EN 50191

Sensor Inputs

Dual channel sensor inputs with earth fault and short circuit detection

Emergency Stop

Separate emergency stop circuit with e-stop buttons and monitored start

Safety Circuit

Dedicated start and stop buttons, fast output disconnection and easy restart